High Performance Elastomer Market Synopsis

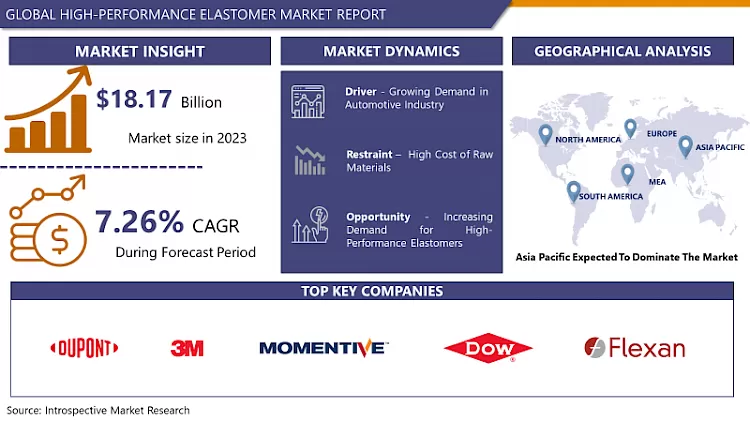

High-Performance Elastomer Market Size Was Valued at USD 18.17 Billion in 2023 and is Projected to Reach USD 34.14 Billion by 2032, Growing at a CAGR of 7.26% From 2024-2032.

A High-Performance Elastomer is a type of synthetic polymer known for its exceptional elasticity, resilience, and durability in demanding conditions. These elastomers exhibit superior mechanical properties, such as high tensile strength and resistance to abrasion, chemicals, and extreme temperatures. They are widely used in industries like automotive, aerospace, electronics, and healthcare for applications requiring reliable and long-lasting flexible components.

- The high-performance elastomer market is increasing demand across various end-use industries such as automotive, aerospace, industrial, and healthcare. High-performance elastomers are known for their exceptional mechanical properties, chemical resistance, and thermal stability.

- The Industry is experiencing continuous innovation and development of advanced elastomeric materials by manufacturers and meeting stringent performance requirements of modern applications. There is a rising focus on lightweight materials to enhance fuel efficiency and reduce emissions in the automotive and aerospace sectors further boosting the demand for high-performance elastomers.

- Furthermore, the expanding applications in medical devices in implantable and surgical instruments, are contributing to market growth. High-performance elastomers offer biocompatibility, sterilization resistance, and long-term durability, making them suitable for critical healthcare applications.

- The ongoing research and development efforts expected to enhance material performance and sustainability are anticipated to create lucrative opportunities for market players in the coming years.

High Performance Elastomer Market Trend Analysis

Growing Demand in the Automotive Industry

- High Performance Elastomers are crucial components in modern vehicles, finding applications in various parts such as tires, seals, hoses, gaskets, and more. The automotive sector is constantly evolving to enhance consumer preferences and regulatory standards. There is a growing need for elastomers that offer exceptional performance characteristics like durability, heat resistance, chemical resistance, and flexibility.

- Automotive manufacturers are enhancing vehicle performance, fuel efficiency, and safety, they rely heavily on advanced elastomer materials to meet these objectives. Furthermore, the expansion of electric and hybrid vehicle segments further increases the demand for specialized elastomers personalized to withstand the unique operating conditions of these vehicles.

- The global push towards sustainability and eco-friendly mobility solutions is driving the development of elastomers with enhanced recyclability and reduced environmental impact. These factors are contributing to the demand for High Performance Elastomers within the automotive industry.

Increasing Demand for High-Performance Elastomers

- High-performance elastomers offer enhanced properties such as temperature resistance, chemical inertness, and mechanical strength, making them crucial in industries like automotive, aerospace, healthcare, and electronics.

- In the automotive sector, high-performance elastomers are utilized in seals, gaskets, hoses, and vibration-damping components to withstand harsh operating conditions and ensure reliability. Similarly, in aerospace, these elastomers play a dynamic role in sealing systems, fuel seals, and O-rings, where performance under extreme temperatures and pressures is essential.

- The elastomers also contribute to the healthcare industry in medical devices, pharmaceutical packaging, and surgical equipment due to their biocompatibility and sterilization resistance. They utilize these elastomers in connectors, seals, and gaskets for their electrical insulation properties and reliability.

- The growing technological advancements and stringent performance requirements across various industries are demanding high-performance elastomers to continue growing in the vast market. Manufacturers and suppliers are leveraging this opportunity to develop advanced elastomeric materials for diverse applications, thereby driving the growth of the high-performance elastomer market.

High Performance Elastomer Market Segment Analysis:

High Performance Elastomer Market Segmented Based on Type and End-User.

By Type, the Nitrile-based Elastomers segment is expected to dominate the market during the forecast period

- The nitrile-based elastomers are a wide range of fluids ideal for use in hydraulic systems, fuel handling equipment, and industrial machinery exposure to diverse substances. The advancements in polymer chemistry have led to the development of specialty nitrile-based elastomers to meet specific performance requirements strengthening their market dominance.

- The growing emphasis on sustainability and regulatory agreement has prompted manufacturers to innovate greener formulations of nitrile-based elastomers, enhancing demand for environmentally conscious industries. The demand for high-performance materials is capable of withstanding extreme conditions offering longevity and reliability. The Nitrile-based Elastomers segment dominates the high-performance elastomer market, driving innovation and shaping the future of elastomeric applications.

By Application, the Automotive & Transportation segment held the largest share of 30% in 2022

- The Automotive & Transportation segment offers exceptional performance characteristics such as high durability, temperature resistance, and flexibility, making them ideal for various automotive applications. These elastomers are extensively used in the production of automotive components like seals, gaskets, hoses, and tires, contributing to their widespread adoption in the industry.

- The stringent regulatory requirements for fuel efficiency, emissions reduction, and safety standards drive the demand for high-performance materials like HPEs in the automotive sector. Manufacturers rely on these elastomers to enhance vehicle performance, reliability, and longevity while meeting regulatory compliance.

- The growing trend towards light-weighting vehicles is improving fuel efficiency and boosting the demand for HPEs, as they offer excellent strength-to-weight ratios compared to traditional materials. The automotive industry's continuous innovation and adoption of advanced technologies also propel the market for high-performance elastomers.

High Performance Elastomer Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast Period

- The Asia Pacific region is of growing importance in various industries, such as automotive, aerospace, electronics, and healthcare. The region's rapid industrialization and growth in these sectors are driving a significant increase in the demand for high-performance elastomers. The automotive sector, particularly in countries like China and India, is experiencing substantial growth, leading to a growing need for elastomers to enhance vehicle performance, fuel efficiency, and sustainability.

- The region's strong manufacturing infrastructure and technological landscape fuel the demand for high-performance elastomers. Countries like China, Japan, South Korea, and India are home to leading manufacturers of elastomers. The skilled workforce and government initiatives promote industrial growth and support the market predictions for high-performance elastomers in the region.

- Investments in research and development, innovate and develop advanced elastomeric materials in the Asia Pacific. The region's demographic trends, urbanization, and rising disposable incomes drive the demand for consumer goods and automotive products. Manufacturers are adopting high-performance elastomers to meet the stringent quality standards and performance requirements of these expanding markets. The favorable economic conditions, expanding industrial sectors, and technological advancements are dominating the high-performance elastomer market in the forecast period.

High Performance Elastomer Market Top Key Players:

- Dupont (USA)

- 3M Company (USA)

- Momentive Performance Materials Inc (USA)

- Zeon Chemicals L.P. (USA)

- Dow Chemical Company (USA)

- Flexan LLC (USA)

- Exxon Mobil Corporation (USA)

- The Chemours Company (USA)

- Reiss Manufacturing Inc. (USA)

- Kaco GmbH + Co. Kg (Germany)

- Kraiburg TPE GmbH & Co. Kg (Germany)

- Wacker Chemie AG (Germany)

- Precision Polymer Engineering Ltd. (UK)

- Daikin Industries Ltd. (Japan)

- JSR Corporation (Japan)

- Asahi Glass Co. Ltd (Japan)

- Mitsui Chemicals Inc. (Japan)

- Tosoh Corporation (Japan)

- Showa Denko K.K. (Japan)

- Shin-Etsu Chemical Co. Ltd. (Japan), and Other Major Players.

Key Industry Developments in the High-Performance Elastomer Market:

- In September 2023, Carbon, a leader in product development and manufacturing technology, announced the launch of EPU 46, its latest elastomer material. EPU 46 delivers high-performance properties, exceptional durability, and a variety of vibrant color options. This innovative material enables the customizable production of premium products such as saddles, footwear, and grips. Carbon continues to push the boundaries of material science, offering superior solutions for diverse applications

- In April 2023, DuPont announced the introduction of new low-cyclosiloxane silicone elastomer blends and silicone resin blends. These developments were aimed at meeting consumer demand for skincare products addressing various skin conditions. The formulations also aimed to comply with evolving REACH regulatory requirements while supporting DuPont and its customers' commitment to Health and Well-Being.

- In September 2021, DuPont celebrated the inauguration of its new medical elastomers mixers at the Healthcare Industries Materials Site (HIMS) in Hemlock, Michigan, USA, with a formal ribbon-cutting ceremony. The investment in the new mixers responded to increased supply needs from DuPont™ Liveo™ Healthcare Solutions customers. The capacity expansion included the expansion of in-house medical-grade silicone elastomer manufacturing capabilities and supported sustainable growth in Liveo™ medical elastomer product lines. It also facilitated the strong growth of in-house production of Liveo™ pharmaceutical tubing dedicated to biopharmaceutical processing, and of medical devices and topical blends.

INTRODUCTION

RESEARCH OBJECTIVES

RESEARCH METHODOLOGY

RESEARCH PROCESS

SCOPE AND COVERAGE

Market Definition

Key Questions Answered

MARKET SEGMENTATION

EXECUTIVE SUMMARY

MARKET OVERVIEW

GROWTH OPPORTUNITIES BY SEGMENT

MARKET LANDSCAPE

PORTER’S FIVE FORCES ANALYSIS

Bargaining Power Of Supplier

Threat Of New Entrants

Threat Of Substitutes

Competitive Rivalry

Bargaining Power Among Buyers

INDUSTRY VALUE CHAIN ANALYSIS

MARKET DYNAMICS

Drivers

Restraints

Opportunities

Challenges

MARKET TREND ANALYSIS

REGULATORY LANDSCAPE

PESTLE ANALYSIS

PRICE TREND ANALYSIS

PATENT ANALYSIS

TECHNOLOGY EVALUATION

MARKET IMPACT OF THE RUSSIA-UKRAINE WAR

Geopolitical Market Disruptions

Supply Chain Disruptions

Instability in Emerging Markets

ECOSYSTEM

HIGH PERFORMANCE ELASTOMER MARKET BY TYPE (2017-2032)

HIGH PERFORMANCE ELASTOMER MARKET SNAPSHOT AND GROWTH ENGINE

MARKET OVERVIEW

NITRILE BASED ELASTOMERS

Introduction And Market Overview

Historic And Forecasted Market Size in Value (2017 – 2032F)

Historic And Forecasted Market Size in Volume (2017 – 2032F)

Key Market Trends, Growth Factors And Opportunities

Geographic Segmentation Analysis

SILICONE ELASTOMERS

FLUOROELASTOMERS

HIGH PERFORMANCE ELASTOMER MARKET BY END-USER (2017-2032)

HIGH PERFORMANCE ELASTOMER MARKET SNAPSHOT AND GROWTH ENGINE

MARKET OVERVIEW

HEALTHCARE

Introduction And Market Overview

Historic And Forecasted Market Size in Value (2017 – 2032F)

Historic And Forecasted Market Size in Volume (2017 – 2032F)

Key Market Trends, Growth Factors And Opportunities

Geographic Segmentation Analysis

INDUSTRIAL MACHINERY

AUTOMOTIVE & TRANSPORTATION

BUILDING & CONSTRUCTION

ELECTRICAL & ELECTRONICS

COMPANY PROFILES AND COMPETITIVE ANALYSIS

COMPETITIVE LANDSCAPE

Competitive Positioning

High Performance Elastomer Market Share By Manufacturer (2022)

Industry BCG Matrix

Heat Map Analysis

Mergers & Acquisitions

DUPONT (USA)

Company Overview

Key Executives

Company Snapshot

Role of the Company in the Market

Sustainability and Social Responsibility

Operating Business Segments

Product Portfolio

Business Performance (Production Volume, Sales Volume, Sales Margin, Production Capacity, Capacity Utilization Rate)

Key Strategic Moves And Recent Developments

SWOT Analysis

3 M COMPANY (USA)

MOMENTIVE PERFORMANCE MATERIALS INC (USA)

ZEON CHEMICALS L.P. (USA)

DOW CHEMICAL COMPANY (USA)

FLEXAN LLC (USA)

EXXON MOBIL CORPORATION (USA)

THE CHEMOURS COMPANY (USA)

REISS MANUFACTURING INC. (USA)

KACO GMBH + CO. KG (GERMANY)

KRAIBURG TPE GMBH & CO. KG (GERMANY)

WACKER CHEMIE AG (GERMANY)

PRECISION POLYMER ENGINEERING LTD. (UK)

DAIKIN INDUSTRIES LTD. (JAPAN)

JSR CORPORATION (JAPAN)

ASAHI GLASS CO. LTD (JAPAN)

MITSUI CHEMICALS INC. (JAPAN)

TOSOH CORPORATION (JAPAN)

SHOWA DENKO K.K. (JAPAN)

SHIN-ETSU CHEMICAL CO. LTD. (JAPAN)

GLOBAL HIGH PERFORMANCE ELASTOMER MARKET BY REGION

OVERVIEW

NORTH AMERICA

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Type

Historic And Forecasted Market Size By End-User

Historic And Forecasted Market Size By Country

USA

Canada

Mexico

EASTERN EUROPE

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Segments

Historic And Forecasted Market Size By Country

Russia

Bulgaria

The Czech Republic

Hungary

Poland

Romania

Rest Of Eastern Europe

WESTERN EUROPE

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Segments

Historic And Forecasted Market Size By Country

Germany

United Kingdom

France

The Netherlands

Italy

Spain

Rest Of Western Europe

ASIA PACIFIC

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Segments

Historic And Forecasted Market Size By Country

China

India

Japan

South Korea

Malaysia

Thailand

Vietnam

The Philippines

Australia

New-Zealand

Rest Of APAC

MIDDLE EAST & AFRICA

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Segments

Historic And Forecasted Market Size By Country

Turkey

Bahrain

Kuwait

Saudi Arabia

Qatar

UAE

Israel

South Africa

SOUTH AMERICA

Key Market Trends, Growth Factors And Opportunities

Key Manufacturers

Historic And Forecasted Market Size By Segments

Historic And Forecasted Market Size By Country

Brazil

Argentina

Rest of South America

INVESTMENT ANALYSIS

ANALYST VIEWPOINT AND CONCLUSION

Recommendations and Concluding Analysis

Potential Market Strategies

|

Global High Performance Elastomer Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 18.17 Bn. |

|

Forecast Period 2024-32 CAGR: |

7.26% |

Market Size in 2032: |

USD 34.14 Bn. |

|

Segments Covered: |

By Type |

|

|

|

By End-User |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Frequently Asked Questions :

The forecast period in the High Performance Elastomer Market research report is 2024-2032.

Dupont (USA), 3M Company (USA), Momentive Performance Materials Inc (USA), Zeon Chemicals L.P. (USA), Dow Corning Corporation (USA), Dow Chemical Company (USA), Flexan LLC (USA), Exxon Mobil Corporation (USA), The Chemours Company (USA), Reiss Manufacturing Inc. (USA), Kaco GmbH + Co. Kg (Germany), Kraiburg TPE GmbH & Co. Kg (Germany), Wacker Chemie AG (Germany), Precision Polymer Engineering Ltd. (UK), Daikin Industries Ltd. (Japan), JSR Corporation (Japan), Asahi Glass Co. Ltd (Japan), Mitsui Chemicals Inc. (Japan), Tosoh Corporation (Japan), Showa Denko K.K. (Japan), Shin-Etsu Chemical Co. Ltd. (Japan), and Other Major Players.

The High Performance Elastomer Market is segmented into Type, End-User, and Region. By Type, the market is categorized into Nitrile based Elastomers, Silicone Elastomers, and Fluoroelastomers. By End-User, the market is categorized into Healthcare, Industrial Machinery, Automotive & Transportation, Building & Construction, and Electrical & Electronics. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

A High Performance Elastomer is a type of synthetic polymer known for its exceptional elasticity, resilience, and durability in demanding conditions. These elastomers exhibit superior mechanical properties, such as high tensile strength and resistance to abrasion, chemicals, and extreme temperatures. They are widely used in industries like automotive, aerospace, electronics, and healthcare for applications requiring reliable and long-lasting flexible components.

High-Performance Elastomer Market Size Was Valued at USD 18.17 Billion in 2023 and is Projected to Reach USD 34.14 Billion by 2032, Growing at a CAGR of 7.26% From 2024-2032.